Medical Modeling and Manufacturing

The MMM area contains 2 Markforged printers (Onyx), an Ultimaker dual-head printer (multi-materials), an Apium medical PEEK printer and a Formlabs SLA printer, and a Artec Micro high-resolution 3D scanner. The MMM area also includes a dedicated space for artificial bone production and a machine shop that includes a Tormach CNC mill, bandsaw, drill presses and grinder.

3D Printers

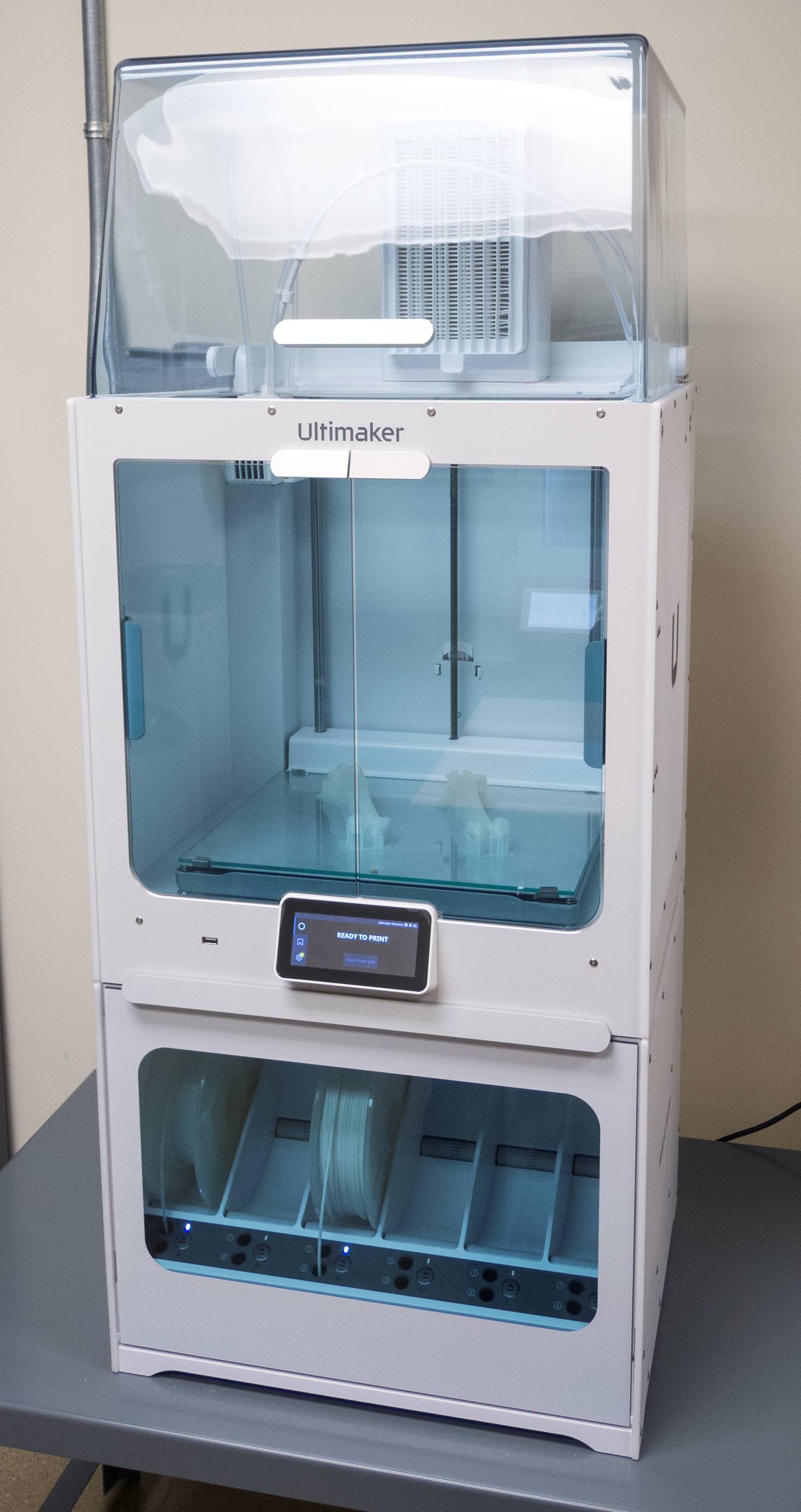

The Ultimaker Pro S5 prints larger volume objects. Materials available are ABS, Nylon, Polycarbonate, PLA, CPE and water-soluble PVA.

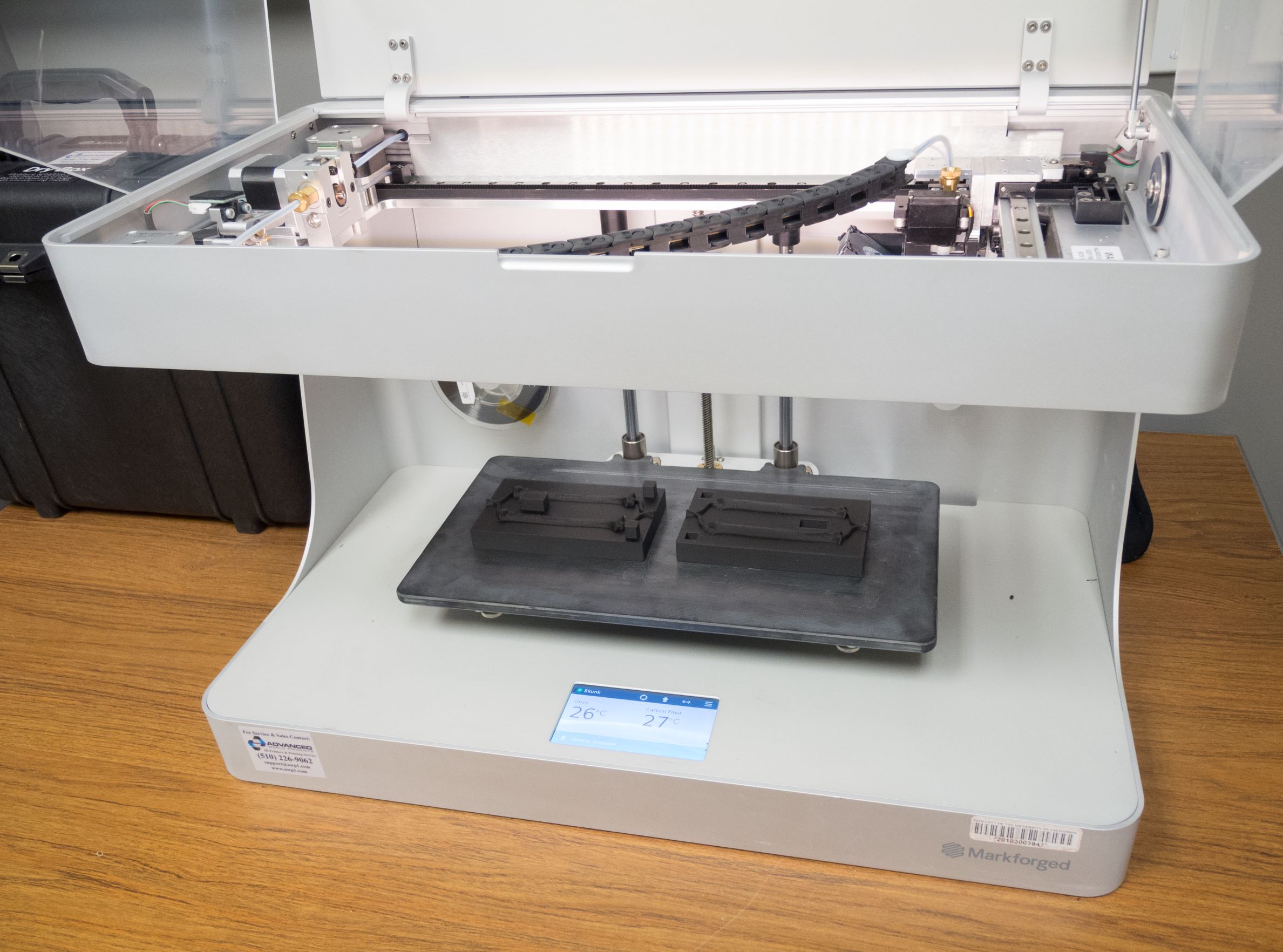

The Markforged Mark2 prints in Onyx which is a carbon-fiber filled nylon. This material is used to print bones for orthopedic surgical practice.

The Formlabs Form2 is a stereolithography printer with many options of material such as dental resins, silicone, and other tough or durable materials. The printer allows for high resolution and fine-detail prints.

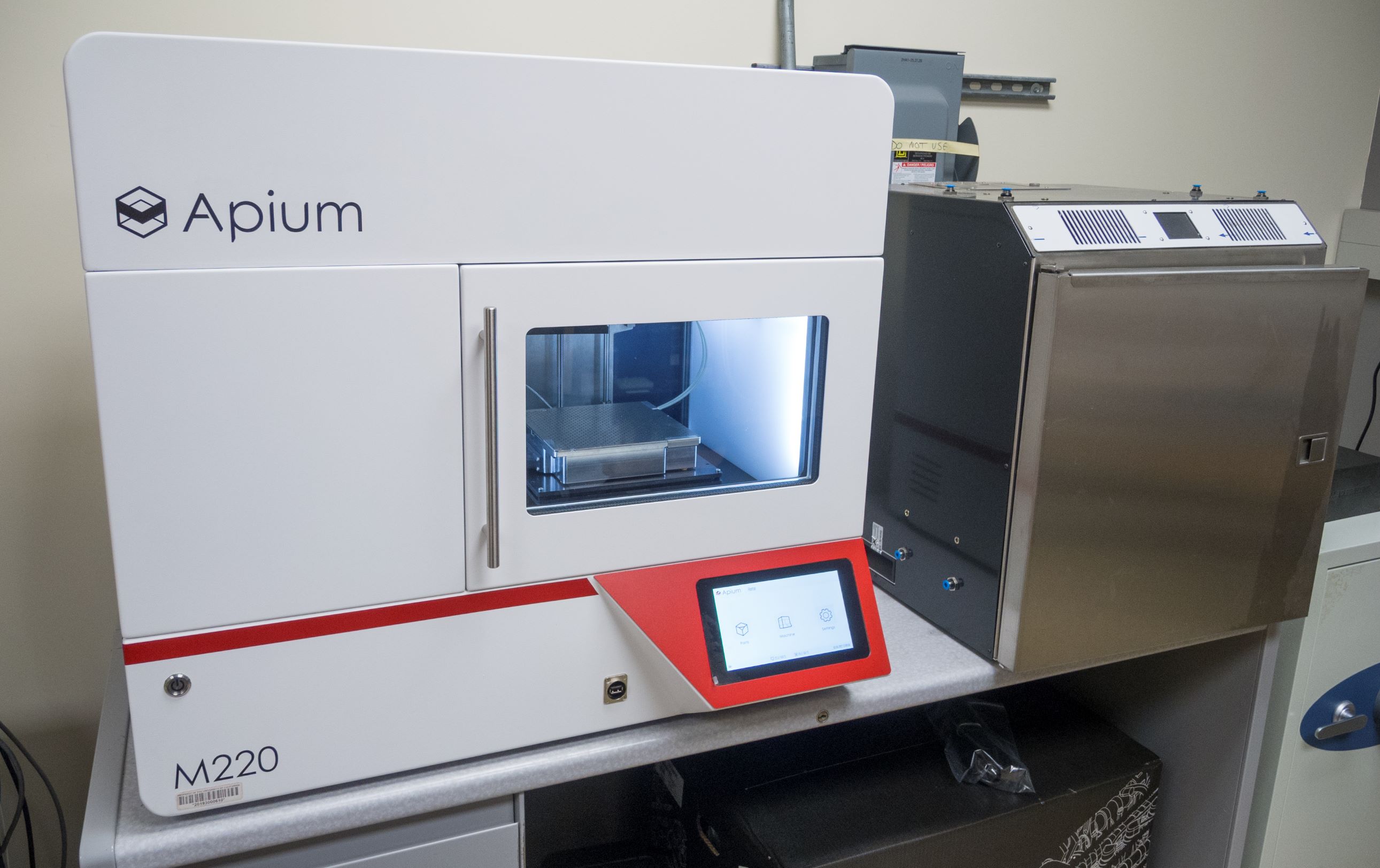

The Apium M220 prints in medical grade PEEK under ISO 10993 standards which allows the material to be biocompatible and implantable.