Medical Modeling and Manufacturing

If interested in any of the following services, please contact Tanya Garcia-Nolan and/or fill out one of the provided submission forms:

External Submission Form (non-University of California affiliation, subject to an increased rate of charge)

Internal Submission Form (University of California affiliation, must have Chart String Account information)

3D Printing

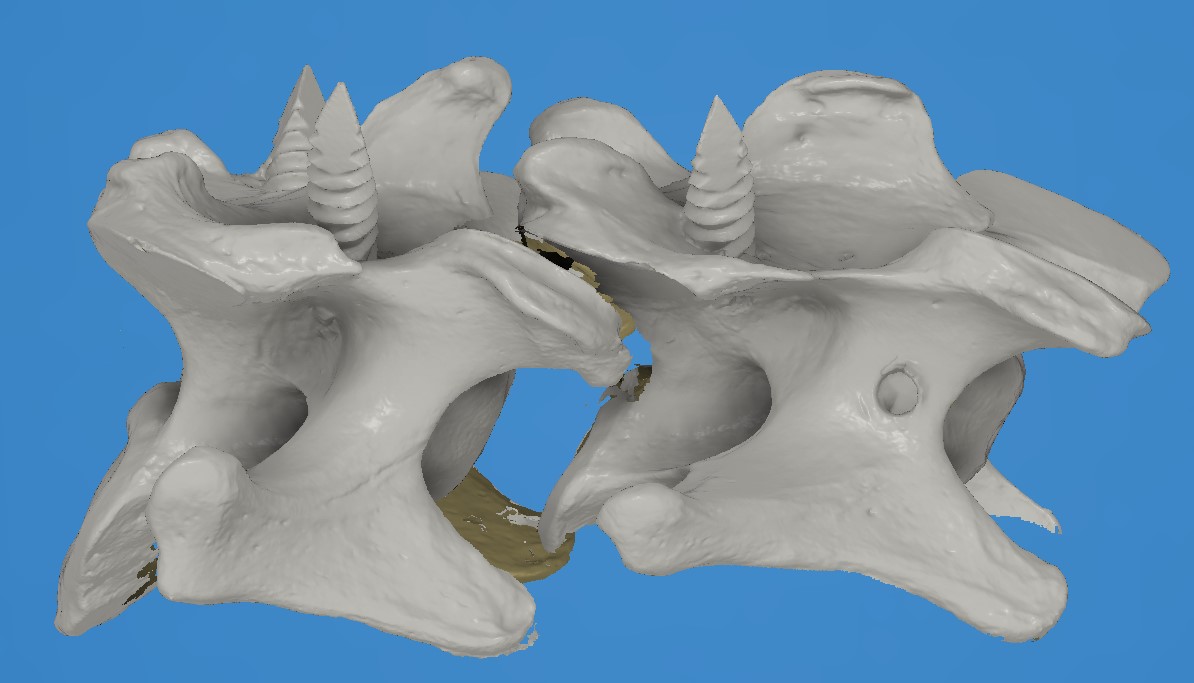

The service provides custom software and expertise to convert a 3D medical image or other medical model to a physical 3D object by 3D-printing it. Custom surgical repair parts may be designed for patients. Custom surgical guides or the patient’s anatomy may be built for surgeons to use to help in surgery or for practice of the surgery. This is provided at a rate of $158/specimen (price subject to change depending on material and size of print).

The Formlabs Form 3BL is a large stereolithography printer for medical devices. It prints in biomedically compatible and sterilizable materials and produces strong detailed prints.

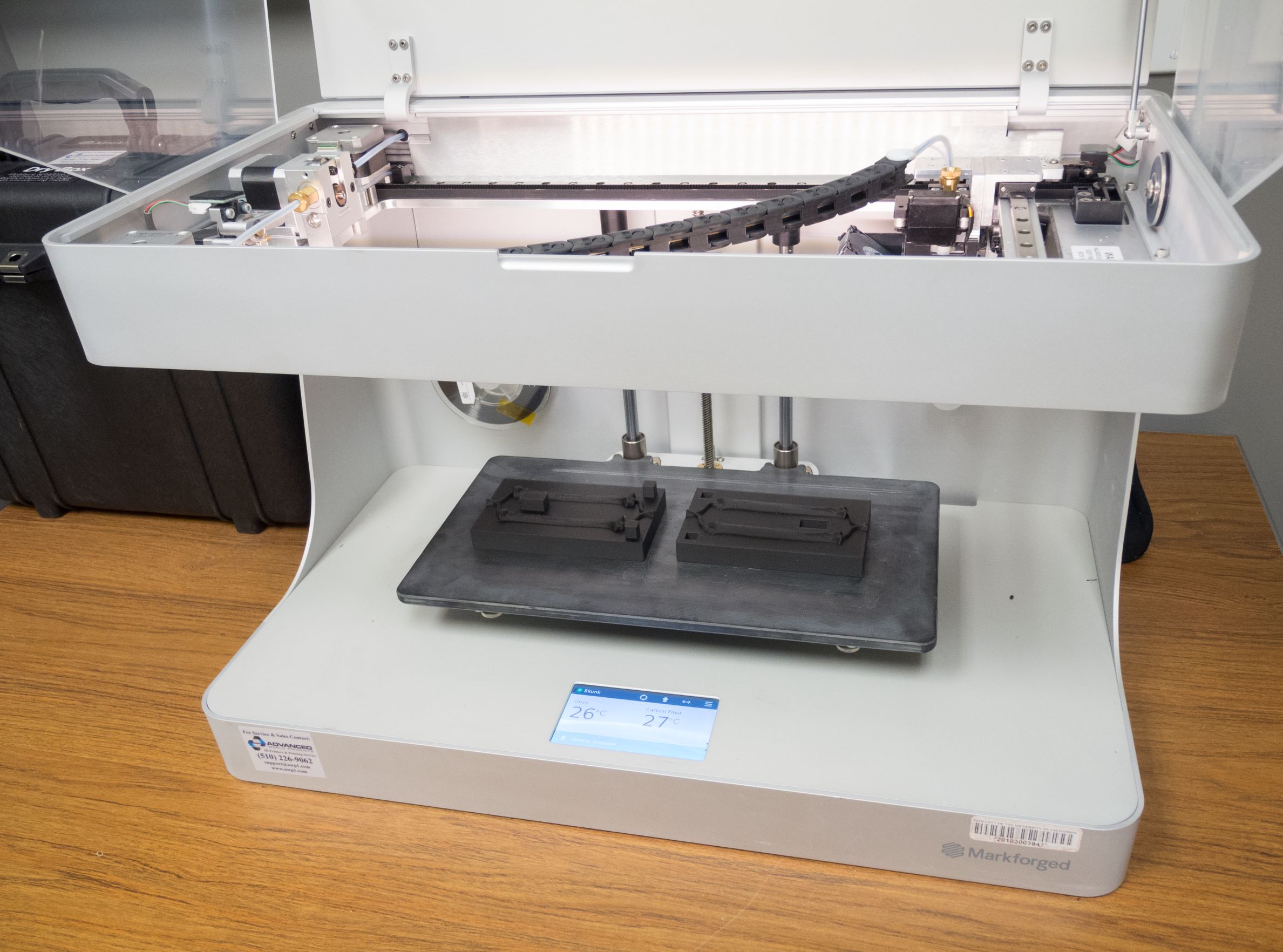

The Markforged Mark2 prints in Onyx which is a carbon-fiber filled nylon. This material is strong and tough. It can be used for functional prototypes or to print bones for orthopedic surgical practice.

The Formlabs Form2 is a stereolithography printer with many options of material such as dental resins, silicone, and other tough or durable materials. The printer allows for high resolution and fine-detail prints.

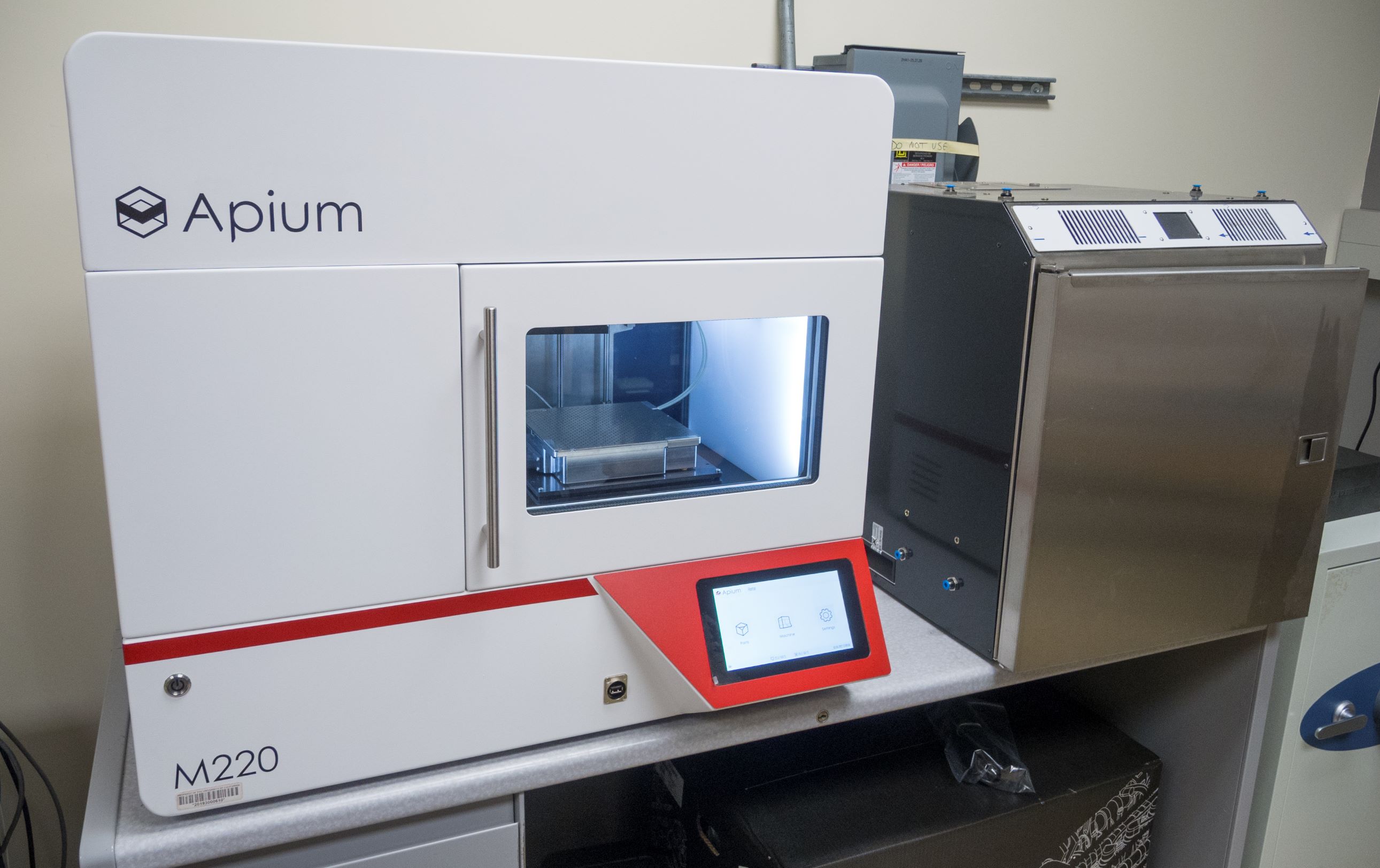

The Apium M220 prints in medical grade PEEK under ISO 10993 standards which allows the material to be biocompatible and implantable.

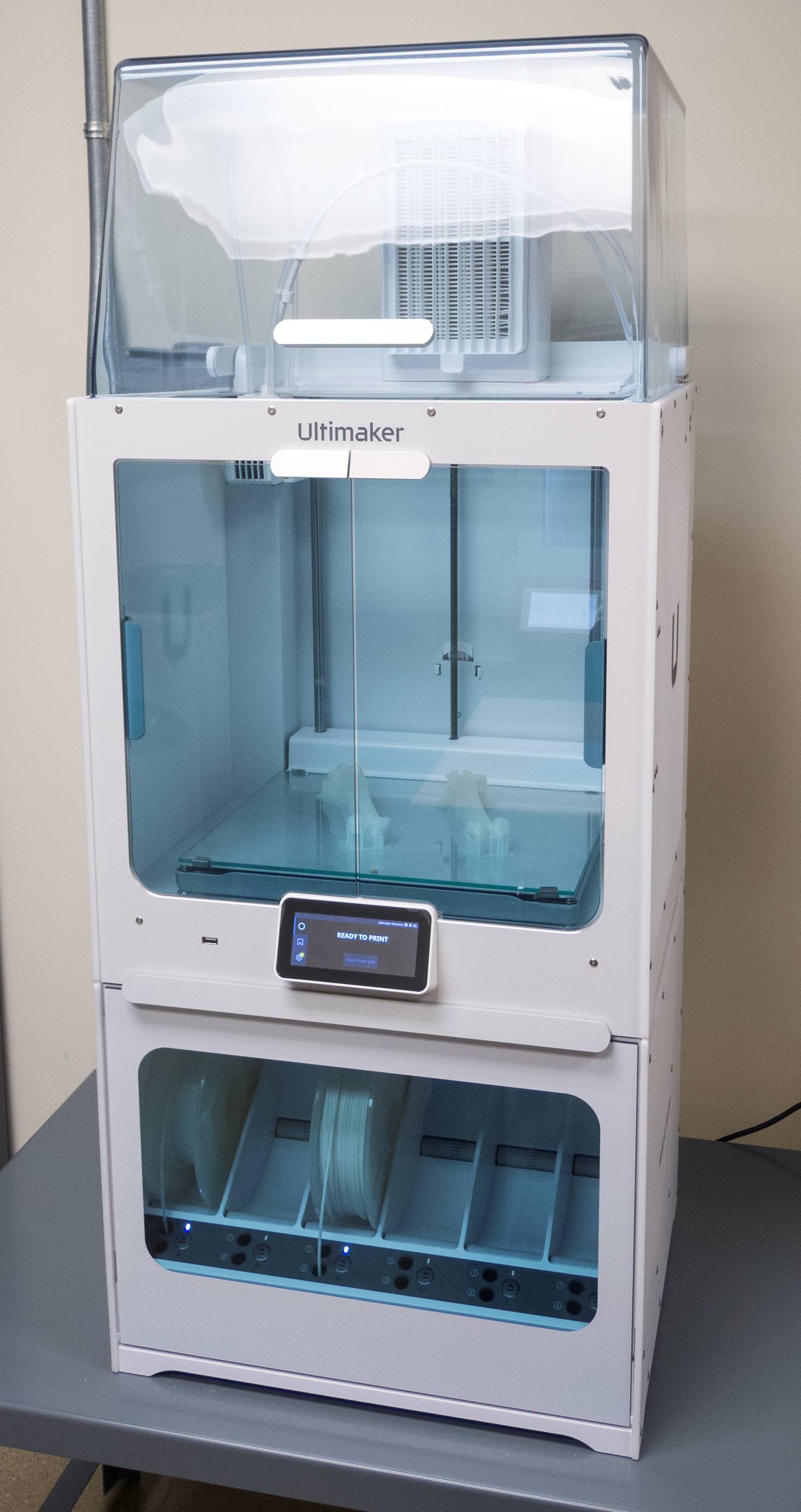

The Ultimaker Pro S5 prints larger volume objects in two materials simultaneouly. Materials available are ABS, Nylon, Polycarbonate, PLA, CPE and water-soluble PVA.

3D Scanning

The service provides a 3D light-scan of small objects in high-resolution. The scan provides a virtual 3D representation of the object for reverse engineering or inspection/analysis. The Artec Micro scans an object to create a virtual representation of it. The resolution is 15-29 microns and has field of view size of 10cm by 5cm by 5cm. This is provided at a rate of $41/hr.

Custom Fabrication

The laboratory can CNC mill metal or plastics to fabricate custom parts. Rates will be determined based on complexity and need for design at a labor rate of $93/hour.

Artificial Bone Production

The laboratory can fabricate bone models that have similar properties as real bones for the purpose of mechanical testing. They are made from custom molds of epoxy resin filled with short glass fibers for the cortex and polyurethane foam for the cancellous and medullary bone. Rates will be determined based on size and complexity of bone, and number of bones needed.