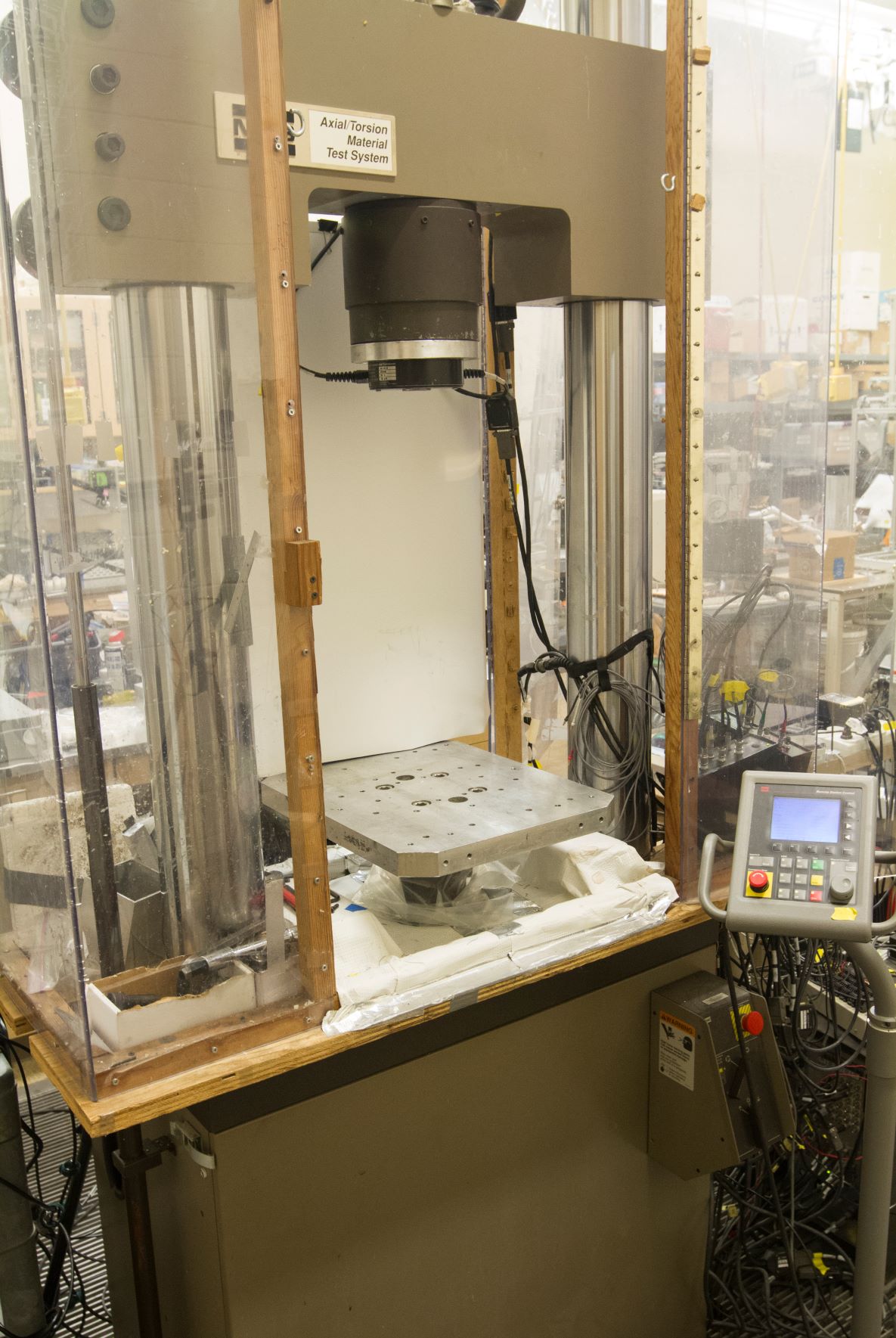

Mechanical Testing

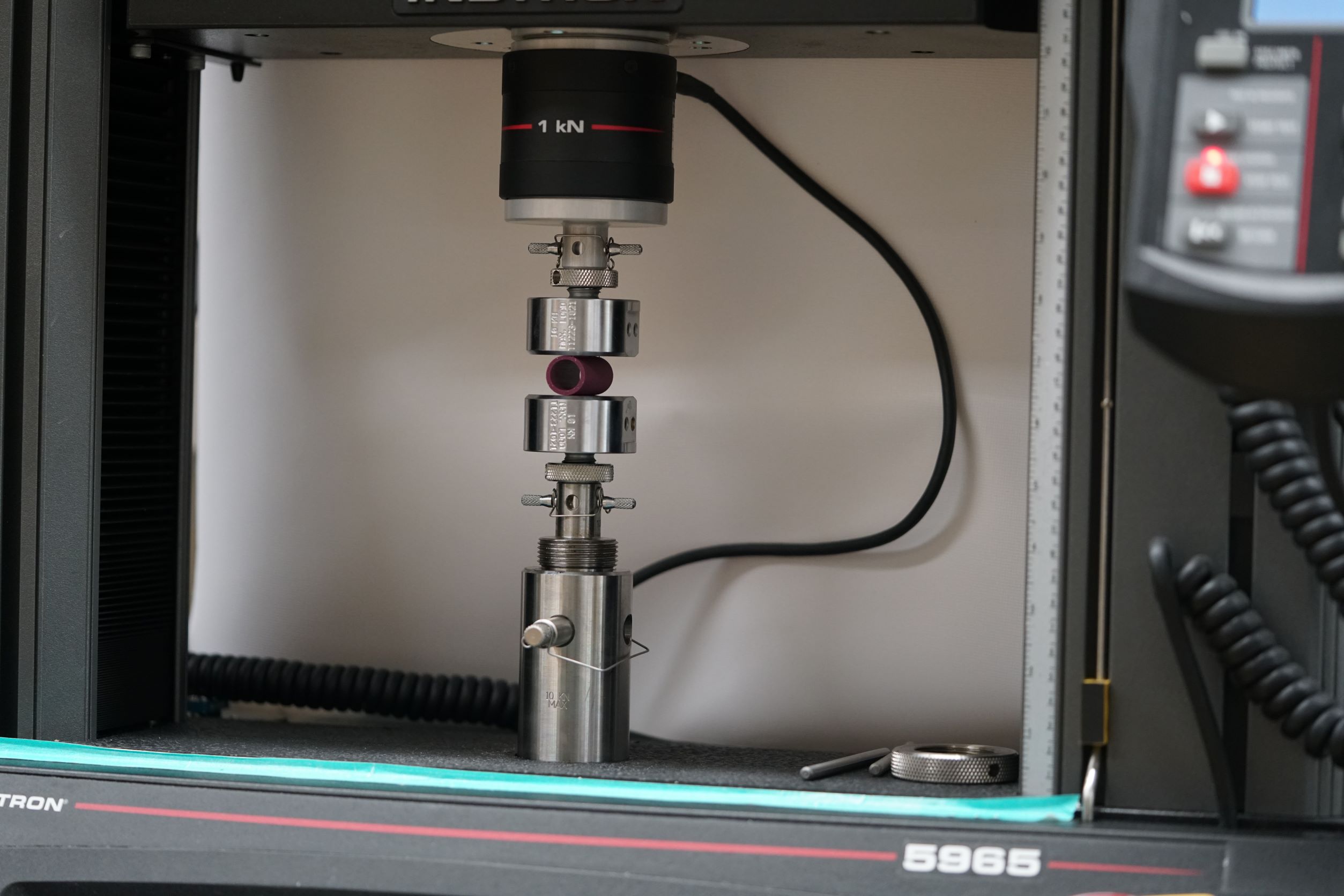

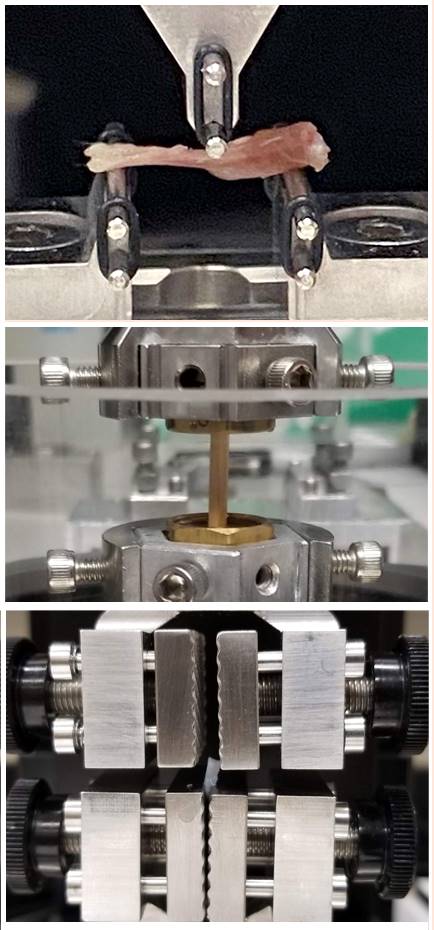

The mechanical testing facility houses a Materials Testing System Model 809 axial-torsional servohydraulic mechanical testing system capable of generating 55,000 lb axial load and 25,000 in-lb torsional load. It has a dual servovalve system and a range of lower load cells to also accommodate small specimens. For medium to small specimens, there is an Instron 5960 single-axis electromechanical system with a 1kN and 50N load cell. For very small specimens and for specialized cartilage indentation mapping or hardness indentation mapping for mechanical properties, there is a Biomomentum Mach-1 with multiaxis 90 N load cell and a 15 N load cell. A third axis is incorporated in the load frame for testing the entire stance phase of stride for cadaveric limbs. Ancillary equipment includes strain gauge signal conditioning equipment, linear variable displacement transducers, linear potentiometers, and extensometers. Other imaging and measurement equipment include a Dantec DIC/speckle strain recording system, a Tekscan pressure sensor system and two high-speed high-resolution cameras (S-PRI) and Vicon Motus software for kinematic or motion analysis. This area also houses a computers with LabView software, a SCXI signal conditioning system and compact DAQ for control and data acquisition on custom made sensing or loading systems.